For Production Work Which Electrode Size Should Be Used

An electrode will require around 40A per mm as a rule of thumb for determining an acceptable current level diameter. As an example lets assume you have a 400 amp power source at 60 duty cycle and need a total combined length of electrode plus work cables of 100 feet.

Electrode Size An Overview Sciencedirect Topics

From the chart the proper cable size to select would be 20 cable.

. As a result while 160A is the recommended current level for a 4mm diameter electrode the permissible working range is. The size of the electrode determines the welding current level. The HgHgO electrode filled with 1 M KOH and the Pt wire were used as the reference electrode and the counter electrode respectively.

1 M KOH solution was used as the electrolyte. An electric current in the form of either alternating current or direct current from a welding power supply is used to form an. Manufacturers propose the usual working range and current.

After two decades of intensive development work in cell line media and bioreactor condition optimization cell specific productivity of over 20 pgcellday can be routinely achieved for production cell lines. A laser with. Cable sizes are increased for longer lengths primarily for the purpose of minimizing cable drop.

For higher current levels two or more cables are often. Hydrogen peroxide H 2 O 2 a green oxidant is widely used in various synthetic protocols Fenton photo-Fenton and oxidation reactions are some of the main processes where H 2 O 2 is used to treat wastewater pollutantsH 2 O 2 is commercially produced by the energy-consuming and hazardous anthraquinone oxidation process One major problem is the. Electrochemical performance of Co II Ch deposited on CP electrode for the catalytic O 2 reduction was evaluated in a N 2 - or O 2-saturated aqueous HClO 4 pH 13 solution containing NaClO 4 0.

1 high titers up to 10 gL and cell densities of over 20 million cellsmL in fed-batch processes have been recently reported by a few companies at major conferences. This work provides insights and guidance to understand the kinetic enhancement of non-equilibrium plasma and the effects of electrode geometries on ignition. Shielded metal arc welding SMAW also known as manual metal arc welding MMA or MMAW flux shielded arc welding or informally as stick welding is a manual arc welding process that uses a consumable electrode covered with a flux to lay the weld.

At a larger electrode surface area and electrode diameter as well as smaller electrode gap size the heat loss to electrode plays a greater role in reducing the ignition kernel size and slowing ignition kernel development.

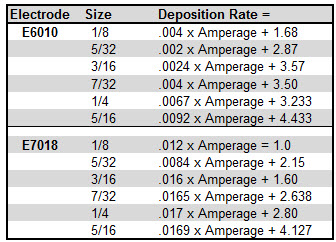

Deposition Rates For Stick Electrodes Welding Answers

Guidelines For Tungsten Electrodes

Selection And Use Of Electrodes For Smaw Of Low Carbon Steel Paktechpoint

Electrode Size An Overview Sciencedirect Topics

Electrode Amperage Chart Baker S Gas Welding Supplies Inc Welding Projects Welding Supplies Welding Electrodes

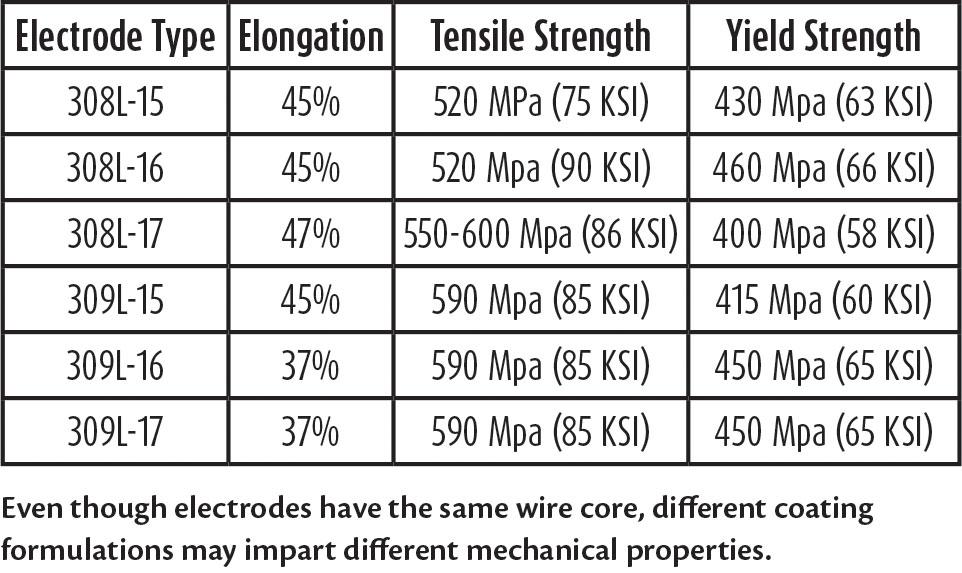

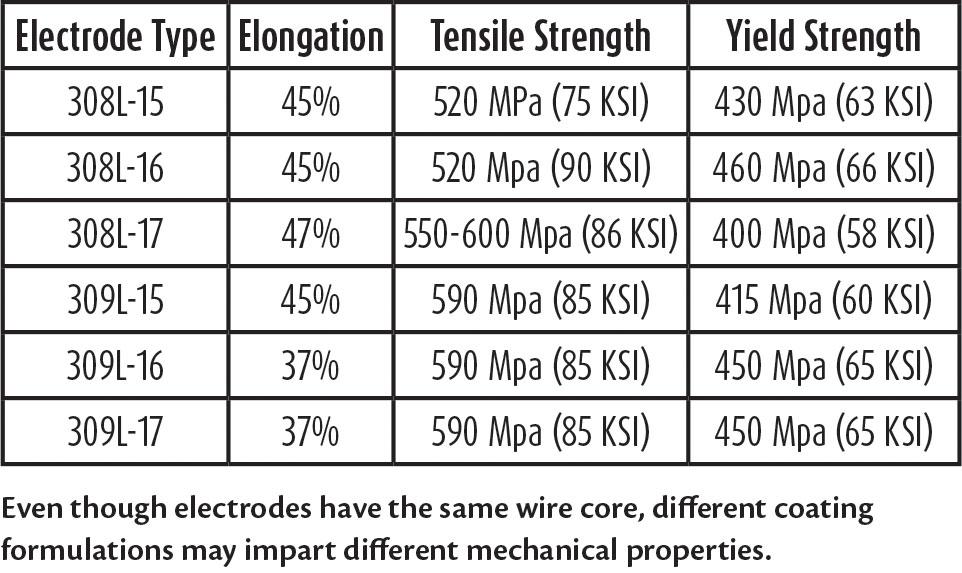

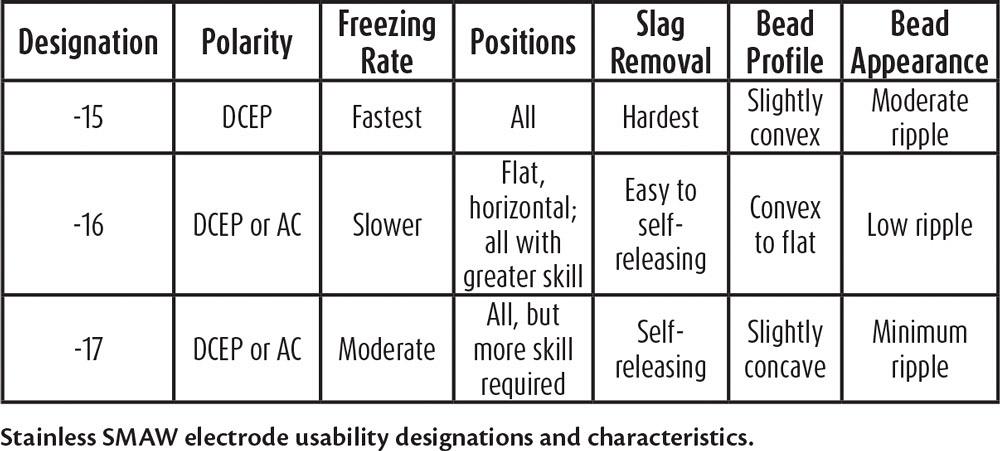

Mastering Stainless Smaw Electrodes

Aluminum Workshop Choosing Tungsten Electrode Type Size For Aluminum Tig

Mastering Stainless Smaw Electrodes

Arc Welding Amperage Settings According To Electrode Size And Metal Thickness Electrodo Soldadura

What Are The Main Applications Of Hdi Circuit Boards In 2021 Circuit Board Digital Camera Notebook Computer

Tungsten Electrode Production Process Cases Packing Gas Tungsten Arc Welding Electrodes

How To Select Welding Amperage Beginner Welding Guide

Guidelines For Tungsten Electrodes

Saturated Calomel Electrode Wikipedia Electrodes Bar Chart Wikipedia

Electrode Size An Overview Sciencedirect Topics

Old School Stick Welding Still Rules 6011 7018 Anyone

Comments

Post a Comment